Is Your Jeep Still Leaking Oil After a Repair? Here’s Why

If you’ve had an oil cooler leak repaired on your Jeep 3.6L Pentastar engine, only to see oil spots under your vehicle again, you’re not alone. Many Jeep owners face recurring leaks because of improper installation or using the same failure-prone plastic part. But why does this keep happening, and how can you ensure your repair lasts? Keep reading to learn what causes repeat oil cooler failures—and how Allied Automotive in Allentown, PA, can provide a permanent fix.

Why Allied Automotive is the Go-To Jeep Repair Shop

At Allied Automotive, we specialize in Jeep repairs and commonly see this issue in newer 3.6L Pentastar engines. Many Jeeps come to us after having their oil coolers replaced at other shops with the same problematic plastic-metal unit. Unfortunately, these replacements often fail again. Instead, we install high-quality, aluminum oil coolers that provide a long-term solution to this recurring issue.

What sets Allied Automotive apart is our precise torque process, which is critical for a proper repair. Many shops overlook this step, leading to unnecessary repeat failures. We ensure each oil cooler is installed using the correct torque procedures to prevent future leaks.

A Reputation Built on Trust and Quality Service

Since opening in 2015, Allied Automotive has built a strong reputation in Allentown, PA, for delivering high-quality repairs and exceptional customer service. Our shop was founded on the principle that auto repair should be done with honesty, transparency, and a commitment to long-term vehicle reliability. We don’t just fix cars; we build lasting relationships with our customers by educating them about their vehicles and helping them make informed decisions about repairs.

Unlike many other shops, we stand behind our work with a 36-month/36,000-mile warranty on parts and labor, ensuring that our customers feel confident in every repair. Whether it’s a Jeep 3.6L Pentastar oil cooler replacement or a full diagnostic service, our goal is to provide peace of mind and long-term solutions rather than temporary fixes.

Understanding the Jeep 3.6L Pentastar Engine and Its Common Issues

The Jeep 3.6L Pentastar V6 is a widely used engine, found in millions of Chrysler, Dodge, and Jeep vehicles. With around 285 horsepower and 260 lb-ft of torque, it provides solid performance and reliability. However, despite its strengths, it has a few well-documented weaknesses that Jeep owners should be aware of:

- Oil cooler leaks – The most common issue, leading to oil pooling in the engine valley and dripping down the back of the engine.

- Cylinder head failures – Early models (2011-2013) had valve seat issues, leading to misfires, particularly on cylinder #2.

- The “Pentastar tick” – A ticking noise from worn rocker arms or cam followers, often requiring repair.

- Cooling system problems – Water pump and radiator failures can lead to overheating if not addressed.

- Oil pressure sensor failures – Sometimes causing oil pressure warnings or low oil pressure issues.

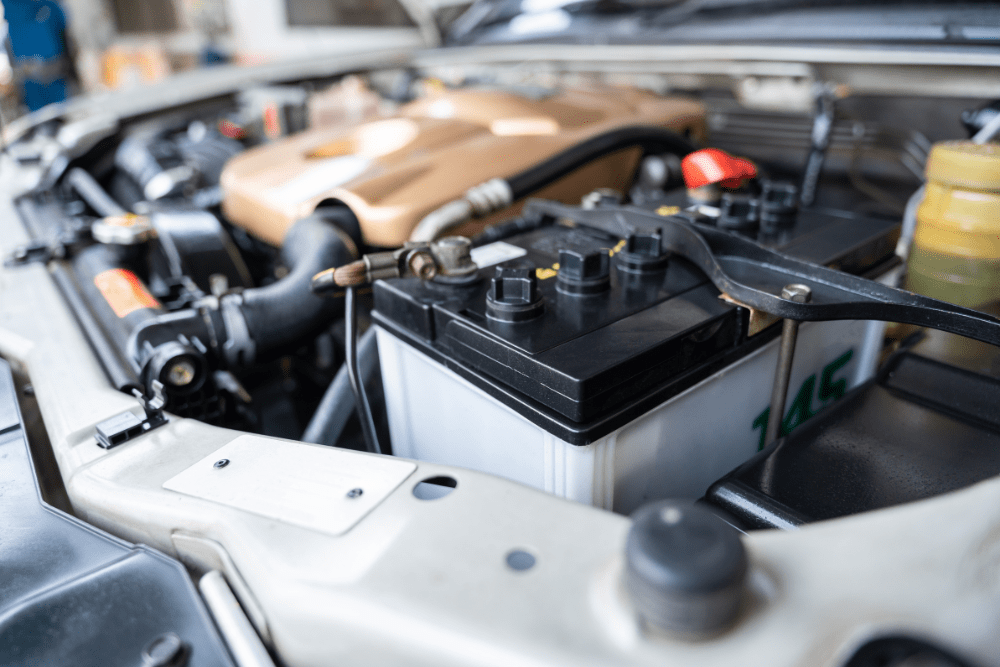

The Common Cause: A Design Flaw in the Oil Cooler Assembly

The factory oil cooler and filter housing are made of plastic, which is prone to warping and cracking due to engine heat cycles. The rubber gaskets also degrade over time, leading to leaks that allow oil to seep into the engine valley and eventually drip down the back of the engine. Many times, these leaks are misdiagnosed as a rear main seal failure.

Symptoms of a Jeep 3.6L Pentastar Oil Cooler Leak

- Oil puddling in the engine valley beneath the intake manifold

- Oil dripping down the back of the engine, near the transmission bellhousing

- A burning oil smell from the engine bay

- Low oil levels and potential oil pressure warnings

Why Some Repairs Fail

If you’ve already replaced your Jeep’s oil cooler and it’s leaking again, one of the following issues might be the cause:

1. Reinstalling the Same Problematic Part

Many repair shops replace the failing plastic oil cooler with another plastic unit. Unfortunately, this means the part is still prone to the same failure. Upgrading to an all-aluminum oil cooler assembly is the best long-term solution.

2. Improper Torque Procedures During Installation

The upgraded aluminum oil coolers are far superior in durability but are less forgiving than the original plastic units when it comes to installation. Many failures occur because mechanics over-torque the part, causing it to bend and create sealing issues. The correct torque specifications must be followed to avoid damage.

Many shops overlook these torque steps, leading to leaks and early failure. At Allied Automotive, we take the time to get it right.

How Allied Automotive Diagnoses an Oil Cooler Leak vs. Rear Main Seal Leak

At Allied Automotive, we frequently see Jeep owners misdiagnosed with a rear main seal failure when, in reality, the issue is an oil cooler leak. While both problems can leave oil near the transmission, rear main seal failures are rare, whereas oil cooler leaks are common in 3.6L Pentastar engines. Our expert team knows exactly how to differentiate between the two to ensure you receive the correct repair the first time.

Expert Diagnosis: Where is the Oil Coming From?

Our trained technicians use proven methods to pinpoint the source of your oil leak:

- Oil in the Engine Valley: We remove the plastic engine cover and inspect the V-shaped valley behind the intake manifold. If oil is pooled in this area or wetness is visible around the oil filter housing, it’s a clear indicator of an oil cooler leak. A rear main seal issue would not cause oil accumulation up top.

- Oil on the Transmission Bellhousing: Our team inspects where the engine meets the transmission. If oil is present on the upper part of the bellhousing or engine block, it likely dripped from above, pointing to the oil cooler. A true rear main seal failure will leave oil at the bottom of the bellhousing—not higher up.

- Leak Pattern and Severity: Many oil cooler leaks start small, with a slight oil smell or a minor drop in oil levels before worsening. A rear main seal failure, in contrast, tends to leak continuously when the engine is running. Our technicians analyze the pattern to avoid unnecessary repairs.

- Oil and Coolant Mixing: In some cases, a failed oil cooler can leak internally, leading to oil mixing with coolant. If we detect oil contamination in your coolant reservoir, we immediately identify the oil cooler as the issue—a rear main seal leak would never cause this problem.

Avoiding Costly Misdiagnoses

We’ve seen countless Jeep owners told they needed a rear main seal replacement, only to find out later that the oil cooler was the real problem. At Allied Automotive, we perform a comprehensive inspection before recommending any repair, ensuring you receive the correct service without unnecessary costs.

What to Expect During an Oil Cooler Housing Repair

Repairing a Pentastar oil cooler leak requires experience and precision. At Allied Automotive, we specialize in Jeep repairs and ensure the job is done right the first time. Here’s what you can expect during the repair process:

1. Intake Manifold Removal

The intake plenum above the engine must be removed to access the oil cooler housing. Since the oil cooler sits in the engine valley, this step involves significant disassembly. While it may seem labor-intensive, it’s far easier and more cost-effective than pulling the transmission for a misdiagnosed rear main seal leak.

2. Removing the Old Housing and Installing the New One

Once access is gained, we:

- Drain the coolant to prevent contamination.

- Disconnect sensors, hoses, and oil lines.

- Remove the old plastic oil cooler assembly and clean the mating surfaces.

- Install a new aluminum oil cooler with fresh gaskets and seals.

3. Torque Procedure: Why It Matters

One of the biggest reasons replacement oil coolers fail is improper torque during installation. Almost all oil coolers that leak again were not torqued correctly. When the aluminum body is removed after a failed installation, it often shows visible bending—proof of over-tightening.

Unlike the factory plastic housing, which could flex slightly, the upgraded aluminum unit must be torqued precisely to prevent leaks. At Allied Automotive, we follow these exact specifications:

- Oil Cooler Housing Bolts: 106 in-lbs (12 Nm) in a crisscross pattern for even seating.

- Oil Filter Cap: 18 ft-lbs (24 Nm) to avoid cracking.

- Oil Cooler Line Fittings: 20 ft-lbs (27 Nm) to prevent leaks.

- Intake Manifold Bolts: Two-pass tightening—first to 44 in-lbs (5 Nm), then to 89 in-lbs (10 Nm).

4. Oil Change & Coolant Top-Off

This job involves draining some fluids, so we always include:

- A fresh synthetic oil change to ensure engine longevity.

- A complete coolant refill and system bleed to remove air pockets.

5. Preventative Maintenance While the Intake is Removed

Since the intake manifold is removed, this is the best time to handle additional maintenance without extra labor costs. While performing this repair, we may recommend:

- Replacing spark plugs (since they’re located under the intake and due around 100K miles).

- Installing new intake manifold gaskets (a must, as they’re one-time-use seals).

- Inspecting/replacing ignition coils or the coolant temperature sensor if showing signs of wear.

6. Final Verification & Testing

Once everything is reassembled, we:

- Start the engine and bring it to operating temperature.

- Check for leaks and ensure proper oil pressure.

- Confirm a leak-free repair before sending your Jeep back on the road.

At Allied Automotive in Allentown, PA, we don’t just replace parts—we fix the problem permanently by using the best materials, following Jeep-specific torque procedures, and performing preventative maintenance to keep your engine running smoothly.

The Allied Automotive Customer Experience

We believe that getting your Jeep repaired should be a stress-free and transparent process. That’s why we go the extra mile to provide excellent customer service:

- Clear Communication – From the moment you bring your vehicle in, we keep you informed about the diagnosis, recommended repairs, and costs. We provide detailed explanations so you understand exactly what’s happening with your Jeep.

- Loaner Cars & Shuttle Service – We know how important it is to keep moving while your vehicle is being serviced. That’s why we offer loaner cars and a shuttle service to make your experience as convenient as possible.

- Complimentary Digital Vehicle Inspections (DVI) – Every vehicle that comes through our doors receives a thorough digital inspection. This includes photos and explanations of any issues found, helping you make informed repair decisions.

- No Surprise Pricing – Before we begin any repairs, we provide an upfront estimate and get your approval. We don’t believe in hidden fees or last-minute add-ons.

Why Choosing the Right Shop Matters

Many Jeep owners come to Allied Automotive after their oil cooler was replaced at another shop, only to have the leak return. This is often due to improper installation or the use of another plastic-metal cooler instead of an upgraded aluminum version. Our experienced mechanics know that proper torque procedures and high-quality replacement parts are the key to a lasting repair.

Why We Stand Behind Our Work:

- Expert Jeep mechanics – We specialize in Jeep repairs and understand common Pentastar engine issues.

- Only high-quality parts – We install all-aluminum oil coolers to prevent repeat failures.

- Precise torque procedures – Ensuring each repair is done correctly to avoid leaks.

- Comprehensive vehicle inspections – Checking for other potential issues while servicing your Jeep.

Schedule Your Jeep Oil Cooler Repair Today!

Don’t risk another failed repair or a misdiagnosed oil leak. Bring your Jeep to Allied Automotive in Allentown, PA, where we guarantee high-quality service and lasting repairs. Our team has extensive experience solving Jeep Pentastar engine problems, ensuring you won’t have to deal with recurring leaks.

Call us now at (610) 351-0020 or book your appointment online.

Visit us at 5580 Quince Rd, Allentown, PA 18106.